ENGINEERING

Product development, 3D CAD design, prototyping and component procurement for integrated solutions.

Product development

From the idea to the customised solution

Integration expertise

At our development centres in Langenfeld and at our production site in the Czech Republic, we develop customised solutions for our customers from various industries. Our engineers and technicians have thought through and tested everything we produce, every component and every design, and made it ready for series production - from delicate plastic parts to complex assemblies.

Development based on partnership

Do you need a solution and have an initial idea? Then you are in the best hands with us. We will advise you personally and contribute our experience to your project. Together with you, we optimise the product during the development phase to ensure highly efficient production later on. In this way, your idea becomes a solution ready for series production - developed in partnership.

3D CAD design & prototyping

State-of-the-art tools and processes

From concept to prototype

With our expertise, we support you from the initial sketch or product idea through 3D CAD design to prototypes that you can touch and test. We work with the 3D design software NX from Siemens. Data exchange is possible via all common interfaces. We can quickly realise initial prototypes using our own 3D printers, in-house prototyping and in collaboration with long-standing partners in the industry. From the initial idea to the finished product, our paths are short. Benefit from our flexibility and decades of experience.

Simulation

Gas-Injection-Technology: Efficient and lightweight

Software simulation of injection molding processes

An example of the use of Moldex3D software to design and optimize the injection moulding process. With our partner Simpatec, we achieve reliable, meaningful and precise results for component, tool and process optimization.

Cooperation to achieve excellent results, get outstanding support by our project teams from the first concept to production.

Simulation of the Gas-Injection-Process:

The CT scan of the real component is shown in blue.

Simulation realized by SIMPATEC (www.simpatec.com)

Advance quality planning

Series quality begins in the design phase

Methodical procedures

Advanced quality planning is the structured approach to project management in the development of new products and processes, using state-of-the-art methods such as FMEA, APQP and project management. Development projects are carried out, documented, monitored and controlled in a structured manner.

Development-related endurance tests

Even the prototype phase is accompanied by extensive, application-orientated tests in our in-house laboratory.

Weak points are thus recognised at an early stage and eliminated before series production begins. An initial sample test report documents that the series product fulfils customer specifications.

Test laboratory equipment

Process controls, quality controls, tests and measurements

Types of tests

Extensive tests are carried out in our laboratories during development and production. These include endurance tests (such as: roller dynamometer with obstacles, repeated lifting test and repeated actuation test for case locks), stress tests (such as: drop test, drum test, jerk test and abrasion test for flocked surfaces, endurance tests for bin locks) and environmental impact tests (such as: climate change test, salt spray test and sprinkler irrigation test).

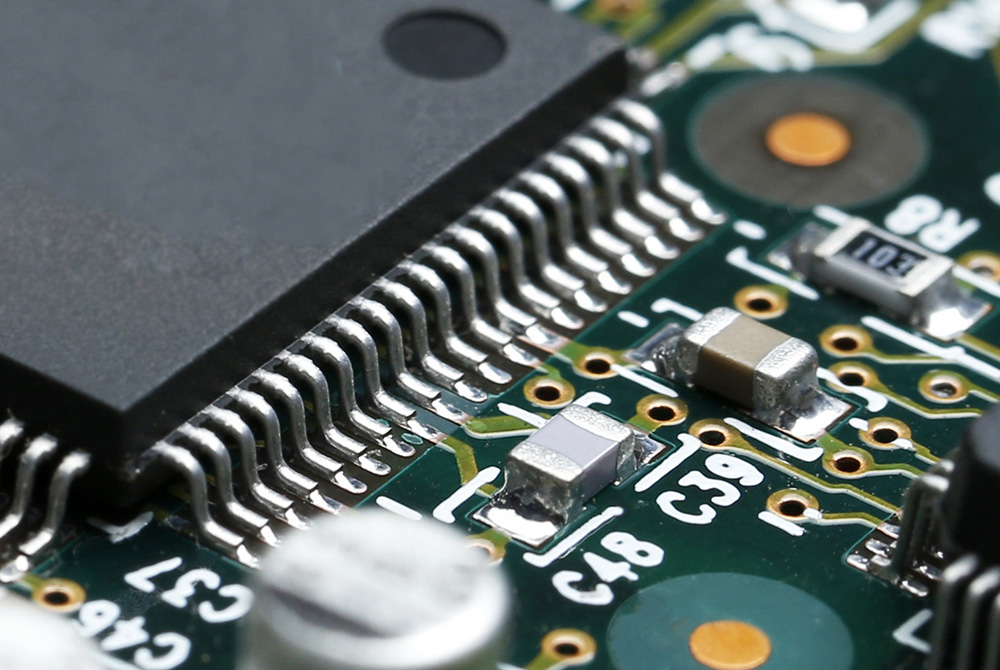

Component procurement

All from a single source

Purchased parts and third-party services

We rely on a global network of suppliers and service providers for the procurement of purchased parts. Quality, reliability and sustainability play a decisive role in the selection of these partners. This ensures that the customer receives a series product from a single source that meets their requirements.

Read more ...